Supply chain planning concepts have been around for nearly half a century, but now many converging factors and technologies are ushering in a new era for this mature supply chain solution. We believe Gartner’s report, “Mastering Uncertainty: The Rise of Resilient Supply Chain Planning”1 takes a challenging stance by imploring supply chain leaders to adapt their planning strategies to better navigate today’s unpredictable markets.

For many years planning processes have been focused on the past–the intermediate result of an accurate demand forecast, capacities and lead times to create a viable plan. But as the Coronavirus pandemic has shown us, the real world doesn’t play by the rules. In the real world a perfect plan is impossible: demand for products can vary widely, a flash flood or last minute promotions can throw all your predictions off. In the report Gartner analyst Tim Payne attests that, “This problem is caused primarily by uncertainty — uncertainty of demand, uncertainty of supply, uncertainty of delivery, etc. Supply chain plans typically take little or no account of uncertainty.” It’s true that no single-number forecast can account for this much variability. Traditional demand forecasting simply can’t keep up. Furthermore, the “continuous planning” we hear a lot about nowadays is appealing–after all, we all want to be responsive to market changes–but it also has problems as it creates potential instability with frequent changes.

Resilient planning offers a way to master today’s uncertainty while still maintaining planning stability. According to Gartner, “Resilient planning is defined as mid- and long-term plans that mitigate against uncertainty by ensuring the right degree of resiliency is built in so that short-term plans are more executable.”

Recommendations for more resilient supply chain planning

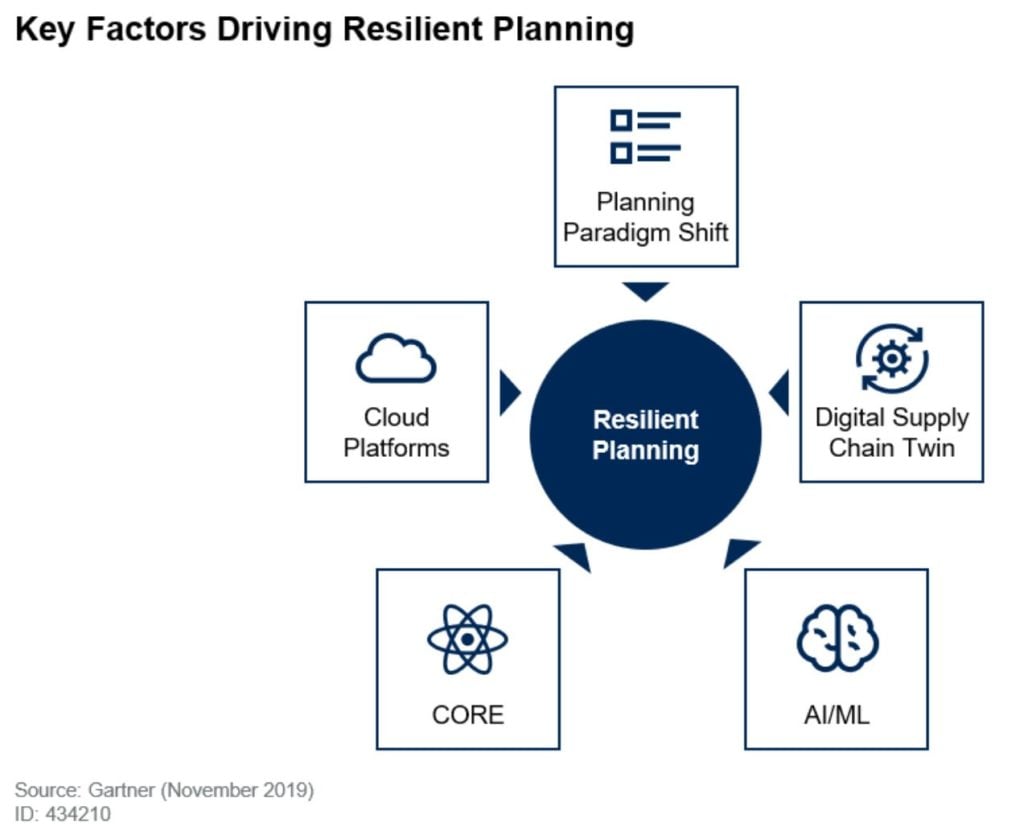

Resilient planning requires new technology and a new way of thinking. How can your company begin to change its thinking to move toward more resilient planning? Gartner offers the following Impacts and Recommendations:

- Change the planning paradigm from deterministic to resilient

- Leverage cloud platforms for hyper-scalability to make more, faster and multiple predictions

- Deploy planning analytics in line with the CORE model to ensure the different planning decisions required are supported

- Use a digital supply chain twin to model and/or simulate the physical supply chain, and align decision making across the supply chain

- Use AI and/or machine learning for better predictions to drive from unknown uncertainty to known variability

Uncertainty is our new normal, and smart companies find ways to ride the waves of volatility instead of being washed away. Cloud-based probability forecasting and replenishment solutions are two examples of technologies which are allowing companies to evaluate huge volumes of supply chain data to make smarter, faster decisions amid changing demand. The more uncertainty present, the more resiliency required. Machine learning is one way a company can in effect “decode” uncertainty to make smarter decisions over time. better understand uncertainty (what factors are correlated) and progressively incorporate that new understanding into its decision making.

Finally, the digital twin is a critical component in resilient supply chains. Gartner states, “With this digital model of the physical supply chain, simulations can be made to see how resilient the proposed supply chain will be to variation and uncertainty.” The digital supply chain twin helps companies evaluate trade-offs and scenarios to make informed decisions about actions to take under different potential outcomes.

Combating market uncertainty with the digital supply chain twin

SKF, the world’s largest producer of bearings, has demonstrated how to create a more resilient supply chain by transforming its planning processes and technology. The company found the size and complexity of its supply chain made it difficult to consistently make optimal trade-offs at the planning level between cash/cost and service. To gain the needed visibility to make these trade-offs and feed accurate, timely data into its planning system, SKF created a “digital twin” of its supply chain. To do this, SKF first created a supply chain network map, a view of how SKF’s items are manufactured, stored, moved, and sold around the world–down to the lowest level of detail, readily available on demand. The next step was bringing the digital twin to life by adding operational data: details like open customer orders, goods-in-transit, and inventory levels. Today SKF feeds data from the central relational database repository into ToolsGroup supply chain planning software to optimize demand, inventory, and planning for all SKU-Locations in its supply chain. It can now more easily sense demand deviations and address them more proactively. Crucially, SKF can optimize inventory levels against desired service levels so that it’s able to compete effectively without incurring excessive storage, transportation costs, and obsolescence. For example, when SKF faces supply shortages, it can now make informed decisions about which warehouses to prioritize sending inventory to, minimizing the impact on customer service levels.

With all the uncertainty around us, planning for the usual is impossible. At ToolsGroup we’re all about being ready for anything–even the unpredictable. It’s time to change the way you think about planning by taking steps toward a more resilient supply chain planning process, and a business that can weather any storm.

For a limited time, access this complimentary Gartner report, “Mastering Uncertainty: The Rise of Resilient Supply Chain Planning”.

GARTNER is a registered trademark and service mark of Gartner, Inc. and/or its affiliates in the U.S. and internationally, and is used herein with permission. All rights reserved.

This graphic was published by Gartner, Inc. as part of a larger research document and should be evaluated in the context of the entire document. The Gartner document is available upon request at this link.

(1) Mastering Uncertainty: The Rise of Resilient Supply Chain Planning, Tim Payne, Published: 15 November 2019.