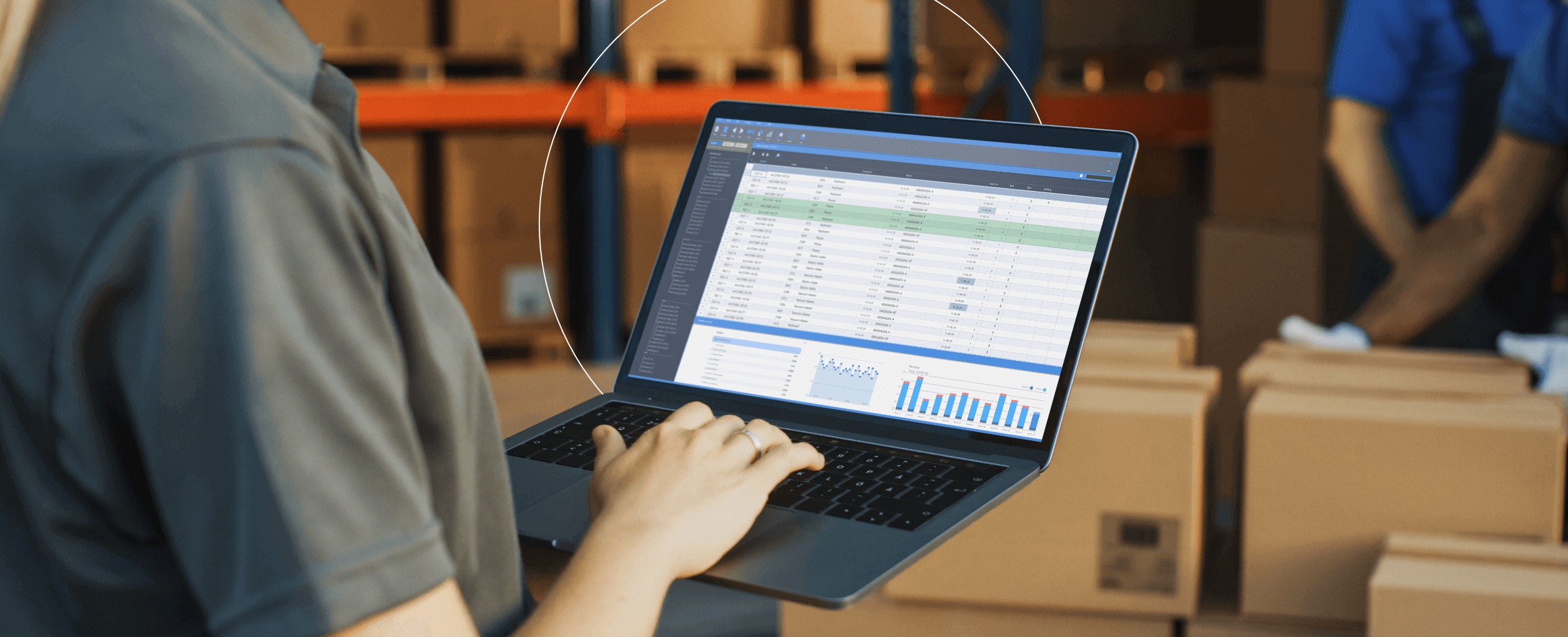

Our Solutions

For your business

Demand forecasting & planning

Demand Forecasting technology provides a self adaptive algorithm that automatically generates a reliable baseline forecast for every SKU Location. Considering numerous factors like variability, daily/weekly and seasonality profiles, promotions, exceptional demand, calendars, etc.

Promotional Planning

Considering past promotional behaviour and its attributes, the ability to predict future promotional behaviour with similar attributes and the effect it has on your forecast. SO99+ then manages the required inventory throughout the supply chain for that promotion.

Demand Collaboration

The Demand Collaboration Hub (DCH) is a web-based consensus forecasting platform that brings together demand and forecast data from multiple sources and stakeholders, allowing service goals to integrate inline with procurement, production, working capital and any supply chain constraints.

Multi-echelon inventory optimisation

Right sizing of inventory at each location in the network considering downstream demand, customer demand and reliability of supply.

Replenishment planning

Time-phased replenishment planning being either purchase orders, distribution or works orders (production orders). Considering multiple supply chain constraints for example, lead times, minimum order quantities, supplier calendars etc.

Production Planning

Time-phased master production schedule, considering constraints like capacity (RCCP), BOM source availability and production shut down calendars.

Minimum Supplier Constraints

The best buy plan, considering minimum order quantities per item and minimum order constraints (weight, cost, etc.) across all items from the supplier.

Sales & Operational Planning

Bridging the gap between sales, operational and the financial plan, versus the ability to execute against that plan.

Dynamic Inventory Policies

Product behaviours of new, growth, maturing or declining differ for every product at every location. Automation of required inventory policies for each behaviour pattern per product to achieve the business objectives.

Range Review

Product behaviours of new, growth, maturing or declining differ for every product at every location. Automation of required inventory policies for each behaviour pattern per product to achieve the business objectives.

Minimum Supplier Constraints

The best buy plan, considering minimum order quantities per item and minimum order constraints (weight, cost, etc.) across all items from the supplier.

The Shenanigiser

Have you ever been in a meeting where you cannot work out why things went wrong? The ability to go back in time and verify what was planned versus what was actually achieved.