From digitalization and changing workforces to trend reversals and inventory overloads, distributors have their hands full when it comes to tackling the latest supply chain challenges.

Over the past couple of years, supply chains have undergone a baptism by fire, having to transform quickly to account for supply shortages, rapidly evolving consumer behaviors, and general Covid-related disruption.

It’s no surprise that things now look a little different in 2022.

Let’s quickly survey the post-pandemic landscape.

- Inventory: In the US, inventory (coupled with accounts receivable and accounts payable) has tied up $1.1 trillion.

- Turnover: The number of supply chain managers leaving their jobs rose 28% between 2020 and 2021.

- Omnichannel: E-commerce is projected to account for 20.4% of global retail sales by the end of 2022.

- Remote Working: Post pandemic studies show that 80% of those surveyed expect to work from home at least three days a week.

- Cyber Security: Global cybercrime damage in 2021 amounted to $16.4 billion a day.

Now that we have a better understanding of the environment distributors are operating in, here are six of the top trends in distribution affecting supply chain planning.

Let’s dig into the details and see how successful companies can turn them to their advantage and overcome obstacles.

1. Decentralization and the Need for a Single View of Inventory

One of the biggest issues distributors are facing is decentralization.

Distribution tends to be a “boots on the ground” operation.

Large distributors have lots of locations, and each location or distribution channel is making individual, autonomous planning decisions.

Because these planners often lack a central strategy and view of inventory that comes with automated planning solutions, these decisions are being made in silos.

The resulting inefficiencies can result in imbalanced inventory and undermine the success of the company as a whole.

This is why more and more distributors are beginning to embrace digital transformation – almost 80% of distributors currently have a strategy in place for it.Digital transformation is not only the next step in effective supply chain planning–it’s a necessary one.See how companies across industries are embracing planning tools powered by AI and automation to shape the evolution of supply chain.

Distributors that adopt automated solutions (like machine learning and multi-echelon inventory optimization) can make planning more collaborative using a single view of inventory that aligns stocking plans throughout the organization.

This degree of visibility and collaboration enables planners to determine optimal inventory levels based on the service level target for each item in a specific location, resulting in increased customer satisfaction, greater control of stock, and reduced working capital costs.

And in this age of inflation, the more effectively you can manage your inventory levels, the more you can decrease your costs and provide your company with a financial buffer.

2. Excess Inventory and the Revenge of the Bullwhip Effect

Distributors tend to be more “purchase-focused” than “demand-focused.”

Some even employ aggressive forward buy tactics, buying stock not because they can sell it quickly but to keep it out of the hands of competitors.

But the inventory situation is starting to flip, making this mindset more of a risk to effective inventory management than ever.

Instead of facing shortages, companies are now flooded with excess stock as the ghost of the bullwhip effect rears its ugly head.

Apply that bullwhip to every autonomously operating, decision-making warehouse or distribution center in a decentralized network, and you’ve got a nightmare situation in terms of working capital, storage fees, obsolescence, and financial losses.

One way to minimize this, besides implementing a solution that provides a single view of inventory, is by making sure you have a central planning team with a defined strategy.

Even better if this centralized team is part of an efficient S&OP process that synchronizes the strategic, tactical, and operational dimensions of your planning processes.

A Retrospective from an Expert

Here’s what Rob Barrett, the Principal, Advisory/Supply Chain Leader at KPMG US, had to say about the post-pandemic bullwhip effect:

“During the pandemic of 2020 and 2021, unfortunately, many of these Bullwhip-inducing behaviors resurfaced, appearing to be a fallback playbook of actions to take in a crisis impact on one piece of the larger value chain.

In the near term, the actions taken may have artificially protected supply, but the long-term impact could plague the supply chain indefinitely. This residual impact includes millions in stranded inventory clogging logistics hubs and lanes…

Historical data will be messy and unreliable. It could be many cycles before data will be stable enough to be confidently used for statistical forecasting, planning, and management of the supply chain.”

So how do you account for fluctuating demand while making sure your stock levels don’t suffer?

A demand forecasting solution that utilizes a probabilistic forecasting method enables planners to differentiate trend from anomaly, assess a range of possible outcomes when calculating future demand, and make strategic decisions about inventory planning.

Want to learn more?

Check out the Four Steps to NextGen Forecasting →

3. Increased M&A Activity

The distribution industry saw a lot of mergers and acquisitions in 2021.

In fact, US industrial distribution M&A activity increased 91% from 2020, and global activity increased 53.6%.

M&A can expand your offering and regional footprint, increase your competitive advantage, and prompt business growth.

But this process doesn’t happen overnight.

Multiple ERPs, varying technological solutions, and disparate planning practices require distributors to build a post-acquisition IT roadmap.

Whether they decide to let the ERPs function separately and sync the data outside of these systems, or instead, consolidate everything into one ERP, it’s common for the execution of your IT roadmap to take years.

In today’s rapidly evolving world of supply and demand, that’s far too slow.

Distributors who want the fast track to improved outcomes must prioritize having a singular view of inventory.

The right unified supply chain solution can give you that visibility by integrating with multiple ERPs. By harnessing the power of artificial intelligence and machine learning, companies can improve forecasts and optimize inventory management.

And the best news?

You can start implementing these supply chain planning solutions early in the post-acquisition stages–without waiting two or three years to execute the lengthy, complicated components of your IT roadmap.TIP: The right solution isn’t just about time saved. It’s about boosting profits through optimized inventory.Wondering what the right automated supply chain solution could do for your business?Check out our Benefits Calculator to see how much your business could benefit from service-driven supply chain planning.

4. Customer Buying Behavior and Omnichannel Trends

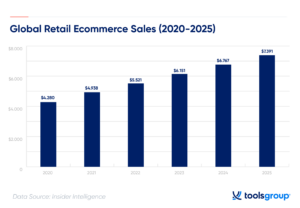

Part of the post-pandemic fallout has been the dramatic shift to ecommerce and omnichannel business models.

According to Insider Intelligence, US ecommerce sales will cross $1 trillion for the first time in 2022, a milestone pre-pandemic speculations did not expect until 2024.

This pattern is demonstrated globally as well, with 2025 worldwide ecommerce sales predictions reaching over $7 trillion.

Many distributors are beginning to build out ecommerce and omnichannel presences to match this growing industry.

Take for instance, Digi-Key, a global, full-service distributor of electronic parts.

Besides offering an online shopping portal, this distribution company has also recently expanded its digital support services to customers through Digi-Key’s Marketplace, which “allows suppliers to leverage the Digi-Key website while housing products at their own location” and averages more than 235,000 visitors a day.

This is just one example of how successful distributors are leveraging new technology and ecommerce opportunities to improve service while attracting and retaining a strong customer base.Not having an item available where and when the customer needs it can severely damage your brand’s reputation, resulting in lost sales and lost customers.The key to managing complexity, right-sizing your inventory, and delivering a positive customer experience?A self-learning planning solution, supported by powerful AI that provides adaptive user collaboration and inventory optimization that targets the best service level for each item at each location.Be the supplier customers depend on. Discover How to Calculate Inventory and Service Level Improvements from Supply Chain Planning Software.

5. Attracting and Retaining Top Talent in the Midst of the Labor Shortage

Like the rest of supply chain, distributors are no stranger to the ongoing talent shortage.

This is due, in part, to a lack of digitalization.

Planners are looking for companies that will give them the tools they need to effectively do their jobs.

And this trend isn’t going away.

In one survey, 80% of Gen Z participants (the latest newcomers to the workforce) aspire to work with cutting-edge technology; 91% said technology would influence their decision between similar employment offers.The right tools can make all the difference to your employees. Empower your planners to work more efficiently and focus on activities that will add the most value to your business.Check out How Automation Elevates the Role of the Planner.

Distributors, who tend to have less focus on digitalization than other industries, have a great opportunity to get ahead of the competition by speeding up their adoption of digital transformation.

It’s important for companies to realize that investing in the right tools and investing in the right people go hand in hand.

The right inventory management solution could not only help limit your holding costs but also retain top talent.

6. Cyber Security

Recent years have seen an uptick in cyber warfare, thanks to the pandemic and geopolitics.

For instance, remote work situations are often not as secure as office-based hardware and systems.

Plus, in the wake of the Great Resignation, former employees sometimes still have access to sensitive information and passwords.

And most recently, the Russian invasion of Ukraine has opened up more chaos and opportunities for hackers to exploit.

Supply chains are especially vulnerable because of how complex they can be and how many parties are involved. In fact, cyber attacks on supply chains increased 51% in 2021.

Here’s how distributors can guard against this growing threat:

- Build a human firewall. 88% of data breaches are the result of human error. Educate your employees to spot phishing attacks and make sure they report them when they see them.

- Maintain your technological assets. Keep a record of how your laptops and phones have been distributed throughout your workforce. Be able to protect and restrict information remotely and simplify the return of assets for departing remote employees.

- Prioritize third-party security. You may be cracking down on cyber threats, but a trusted vendor may not. Hackers can exploit the vulnerabilities in a partner’s network to infiltrate yours as well.

Utilizing Distribution Trends To Right-Size Inventory

At the end of the day, distributors need to achieve right-size inventory in order to reduce supply risks, maximize profitability, and build a loyal customer base.

When it comes to achieving this, remember to account for the current distribution trends:

- Invest in the right automated forecasting and inventory solutions that can synchronize planning operations, provide a single view of inventory, set optimal stock levels, and reduce grunt work so employees can focus on value-added activities.

- Adapt your business for omnichannel and ecommerce opportunities to better serve the growing base of online shoppers.

- Look for vulnerabilities in your systems and make sure your employees are trained to spot and respond appropriately to cyber attacks.

Ready to take action on the latest distribution trends?

Start with the basics. Get your free guide to Machine Learning for Supply Chain Planning to equip your planners with the right tools to manage inventory levels and increase profitability.

The source of this article is from ToolsGroup

By Mary Vasile