Inventory Planning Services

is about delivering results.

01 Services

Managed Planning Services

FinStock’s Managed Planning Services deliver continuous inventory planning configurations and solutions to adapt to the dynamic nature of supply chains for your company to achieve its objectives.

Software as a service

FinStock offers a web-based subscription model for the software. FinStock further provides technical support and maintenance but excludes operational support.

Strategic Supply Chain Consulting

FinStock believes in strategic advisory services that analyse risks and opportunities for clients, working with you to develop a detailed strategic roadmap for your company.

02 Solutions

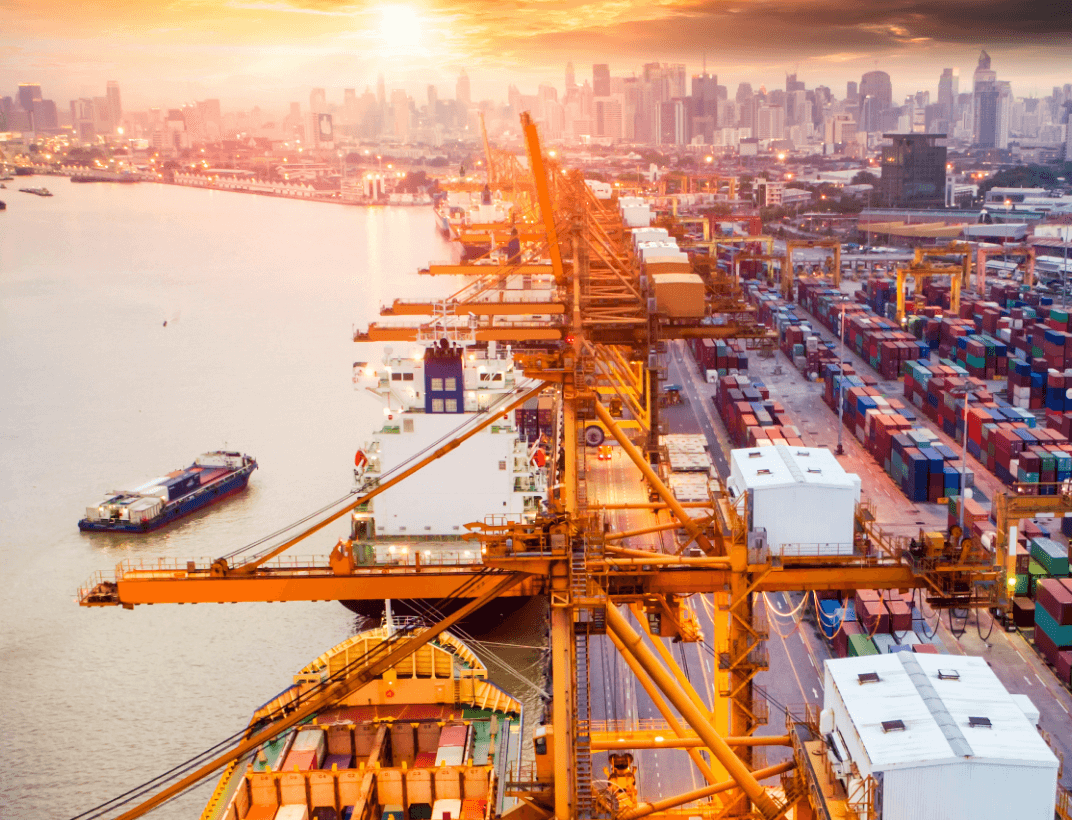

INVENTORY PLANNING

Balance your inventory investment and allocate resources to your high-performing, profitable products with powerful insight and trusted recommendations.

Business process management

Business process management allows you to achieve focus, control, alignment, and superior business results by developing integrated sales and operations planning strategies.

Supply chain analytics

Adapt to changes in lead times by measuring and assessing suppliers’ performance. Provide your customers with the service levels they expect based on supplier reliability. Identify trends in your supplier network to optimise and improve it.

03 Partners

04 About Finstock

Our team of experts use best-of-breed software to optimally manage your inventory and business processes.

We expect to improve your inventory value in a sustainable way and work closely with your team, empowering them to sustain the improvements and release more benefits for your business.

Our software analyses demand history across multiple dimensions so you can achieve the most reliable forecast and inventory targets for mastering demand volatility and delivering service level excellence.

Our innovative and advanced technologies enable you to improve and automate your planning process. Our solutions span key supply chain planning areas such as Demand Planning, Demand Sensing, Promotion Forecasting, and Inventory Optimisation.

05 Clients

06 Blog

When It Comes To Excess Inventory, Prevention Is Better Than Cure

Excess inventory – it’s taking up your warehouse space, tying up working capital, and limiting your planning team’s range of motion. It’s time to Marie Kondo your supply chain by eliminating excess inventory and learning how to avoid it in the first place. Let’s talk...

Seasonal Inventory and 7 Ways to Manage It Effectively

My eight-year-old self counted down the days to October 1 – the day my mother finally let me bedeck her spotless house with cobwebs and window clings of ghosts and goblins. It never occurred to me then that someone had to decide how many pumpkins to stock in my little...

Inventory Control in Manufacturing: 7 Strategies to Maximize Service Levels and Profit Amid Disruption

Like most industries, manufacturers around the world are feeling the pinch of inventory disruption brought on by shortages and other supply chain challenges. But manufacturers are unique. Unlike many businesses who sell finished products, manufacturers...

Contact Us

FinStock Pty Ltd,

2 Rhodes Link Avenue

Paardevlei, Somerset West

7130